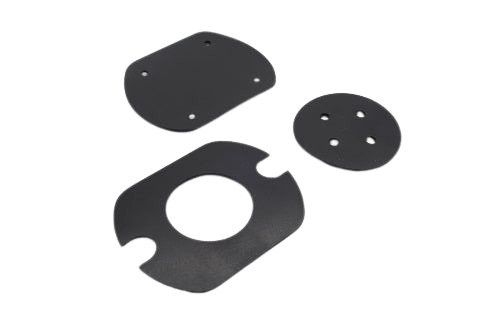

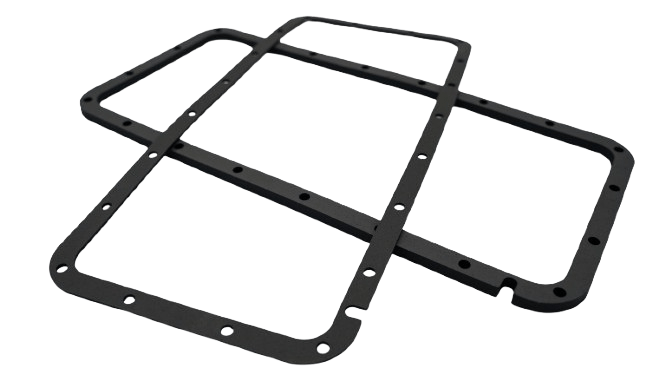

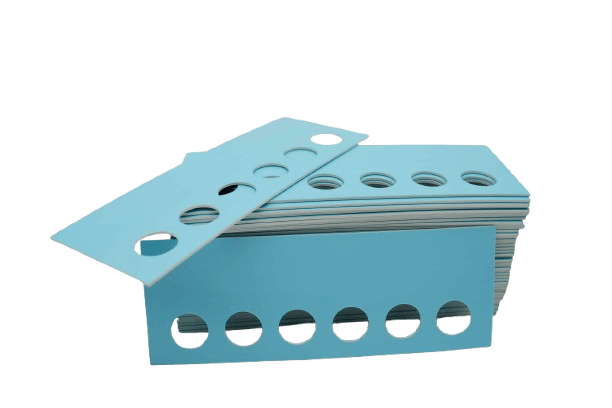

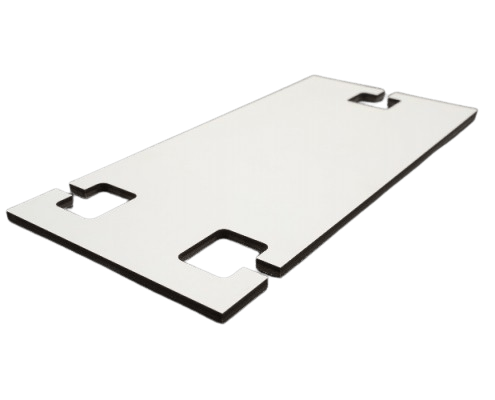

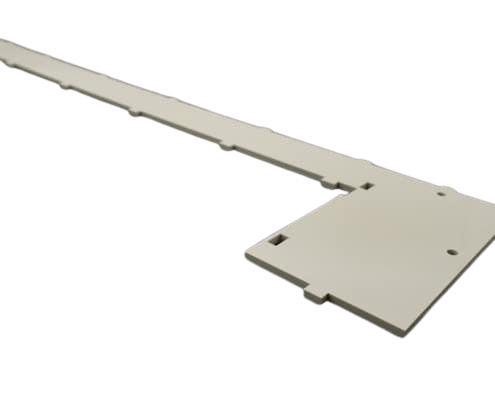

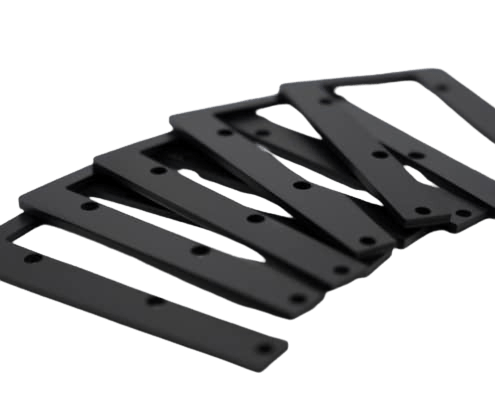

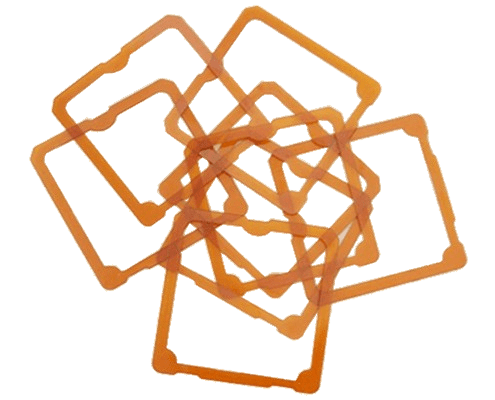

PS (Polystyrene)

Plastic

Polystyrene (PS) is a thermoplastic polymer known for its clarity, rigidity, and cost-effectiveness. The material is lightweight, easy to process, and offers an excellent surface gloss. PS is available in both solid and foam forms, making it highly versatile for various industrial applications.

Well-known trade names of PS include Styron®, Novacor®, and Lustrex®. These grades are commonly used in the packaging industry, display technology, and household appliances.

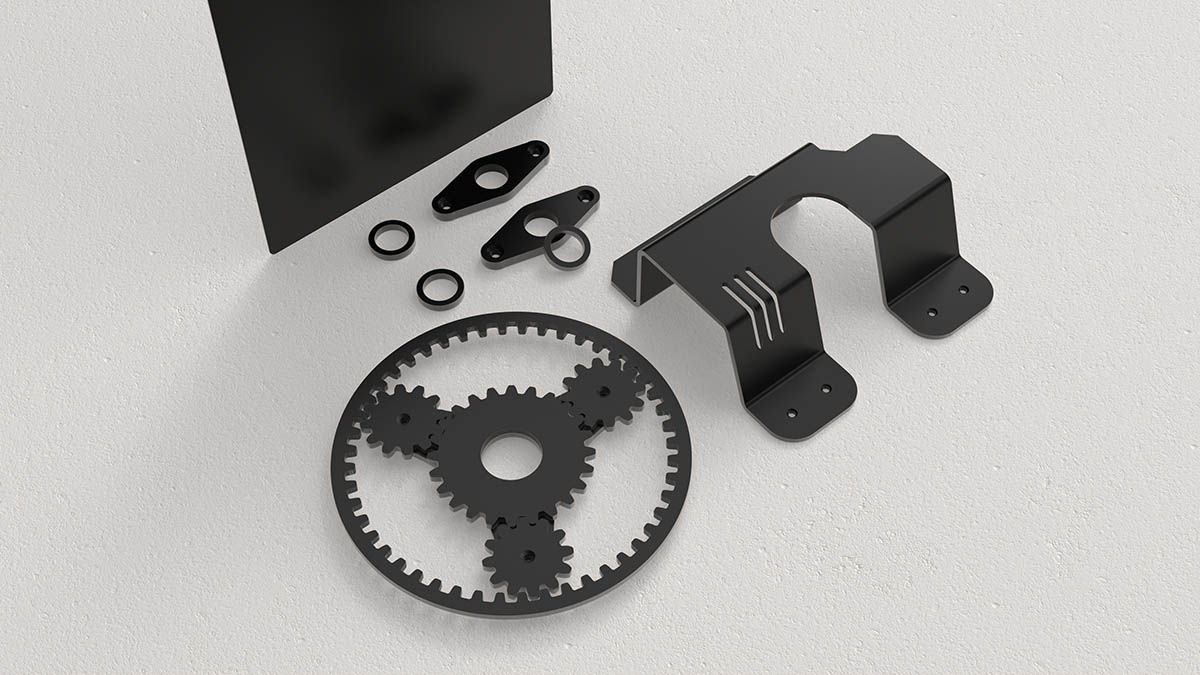

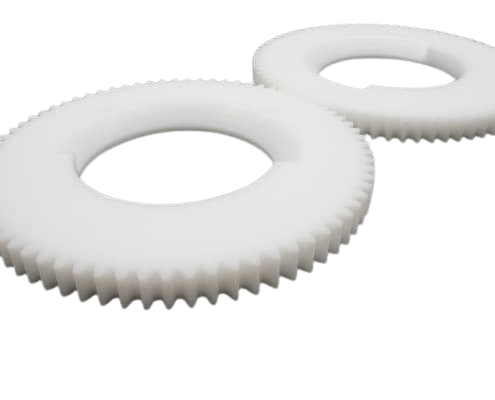

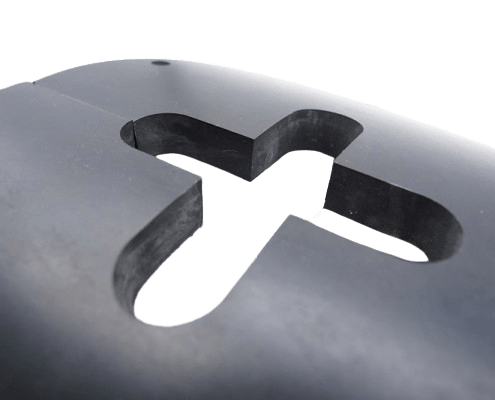

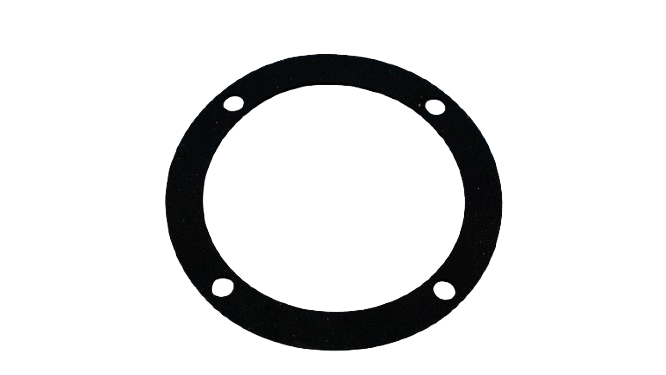

- Laser cutting

- Milling